Artwork

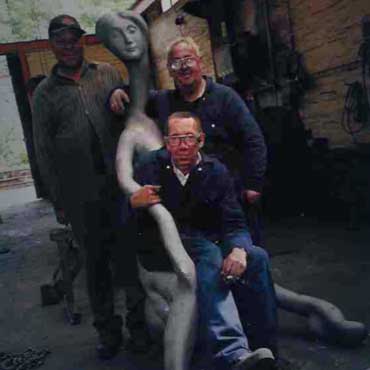

Dave Bradbury

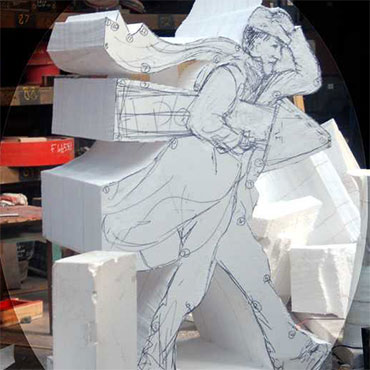

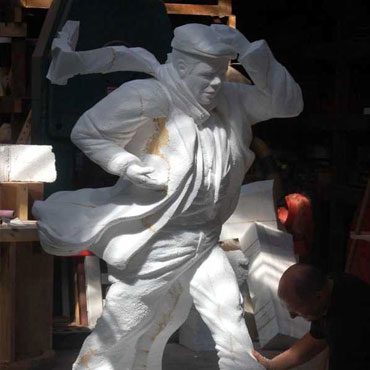

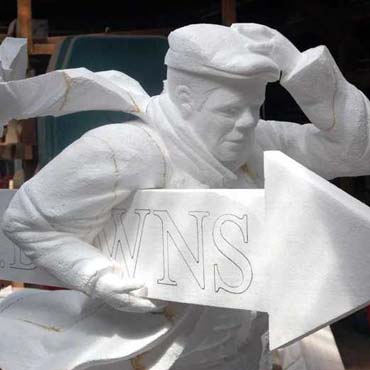

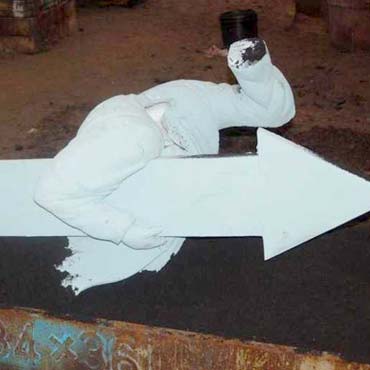

The Customer, commissioned by H.Downs & Sons

The image was presented to us in a selection of sketched ideas. We chose this one, which was then transferred to the block of polystyrene to allow Dave to start to carve the figure.

The statue takes shape as a solid lump of polystyrene. The next stage is to separate it into smaller pieces so it can be lightened and cast. The arrow, although a separate piece, will be part of the casting. The letters will be cast in aluminium separately and riveted on to form a contrast to the rusting iron.

Adam Reynolds

Pit Pony & Coal Tub

A hill top memory to the pit ponies who worked below ground in the mines.

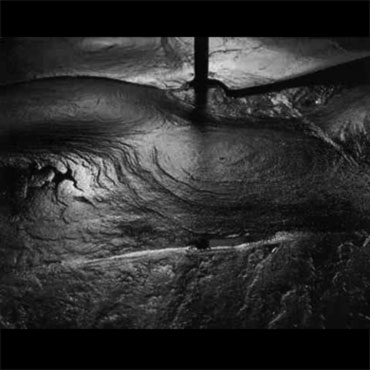

Guiseppe Penone

Contour Lines

Our first art castings which negatively reflected the wear and tear of the steps within Dean Clough Mills at Halifax over the years since it was built.

Photographs courtesy of Susan Crowe

Peter Burke

Janus Heads

A very effective use of the inside and outside shapes of a mould. Peter identifying in the moulds for plaster casting, saw the faces and enlarged the moulds. Each side are the same castings seen from the outside and inside. The head is made from two pieces ,which are bolted together along the seam on the shoulder.

The pieces were commissioned by Sculpture at Goodwood and have been transported to California for a private collection.

Michael DanArcher

The Cambridge Sculpture

Sited at the offices of the Government Ministry DEFRA, the Inland Revenue and the Regional Government GoEast. Brooklands Avenue, Cambridge. The text on the Cast Iron refers to Gog and Magog, the legendary giants who sleep under the Downs south of Cambridge. They were in love with the river goddess Granta. The river Granta (now the Cam) flows through Cambridge.

The cast iron represents the ancient Neolithic standing stones and legends such as Gog and Magog.

The granite comes from Quanzhou in Fujian province, China. It is called Tiger skin because of its patterning.

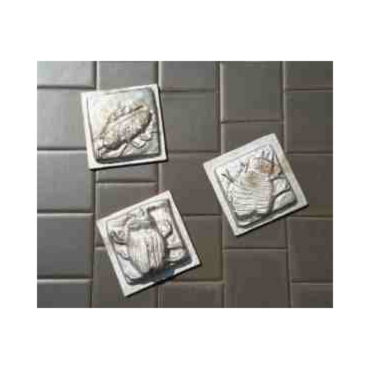

Amanda Wray

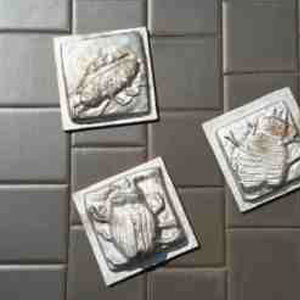

Insects and Bugs

Tiles created by school children and Amanda Wray as part of a fascinating school project. The children helped to craft the "insects and bugs" out of clay, they were then cast by us in aluminium. The tiles are going adorn the playground where the other children can admire the textures the aluminium shows.

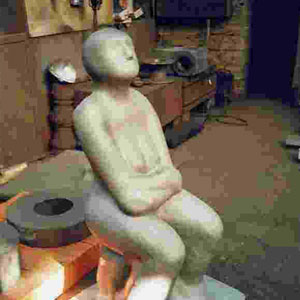

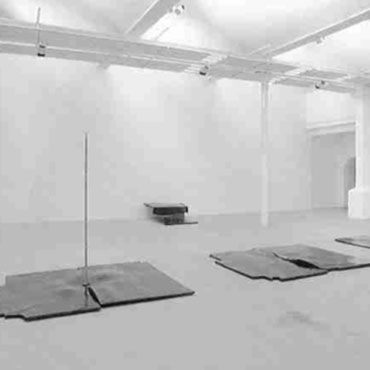

Jason Thomson

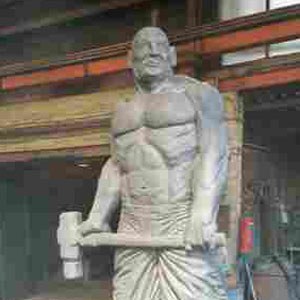

Parkway Man

Jason's ambitions and commissions get bigger we were asked how large we can cast and Jason went out and bought an equally large piece of polystyrene out of which he was to carve his next sculpture. The commission of a strong steel worker back to Sheffield was asked for by Sheffield City Council's Parks, woodland and countryside unit as part of their Lottery Heritage money.

Project set up called 'fuelling a revolution' to commemorate the ancient woodlands around from which the industry emerged. The finished sculpture will be placed at Bowden Houstead Wood, and will be seen set back from Parkway the main road from Rotherham to Sheffield. A61.

In relation to the statue, Jason takes on the appearance of a national elf worker. Having sketched the shape he wants of the statue he starts to carve away the excess. 1 kg of polystyrene converts to roughly 500 kgs of iron. His target weight is 3 tonnes so a finished weight of 6 kgs. for an eleven foot man.

Nearly finished, hollowed out at the studio when weighed at the foundry, this chubby chap came in at 12 kgs. So for the next two days Jason removed 6 kgs from the inside leaving a wall thickness 20-30mm. Discussions were held before Jason had started to carve regarding how the sculpture would be moulded and he built in what had been, asked making everybody's life easier.

Coralie Turpin

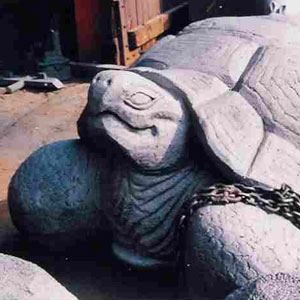

Menagerie à trois

A selection of castings used to decorate an urban regeneration site at Swinton Rotherham. The statues have all been produced from polystyrene, carved by Coralie and cast in iron. The iron gives a hard wearing and strong finish to these sculptures which are meant to be played and sat on and there to adorn an area used for play and recreation.

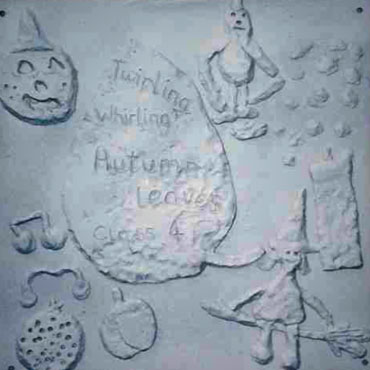

Brockholes Primary School

The Four Seasons

Art work by the children of Brockholes Primary School Huddersfield. Starting with 4 pieces of ply and some plasticine the children were given a theme of the four seasons to produce wall mountings in iron.

Each plaque was made by a group a children within the class, when completed they were brought to the foundry to be cast. They will eventually all be sited on the playground walls.

Jason Thomson

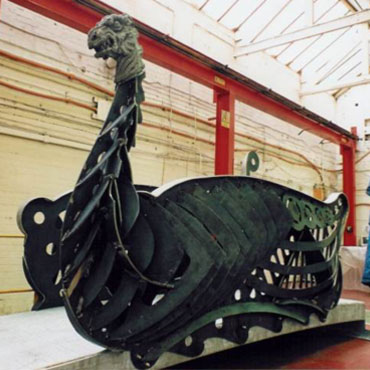

Birchwood Bridge

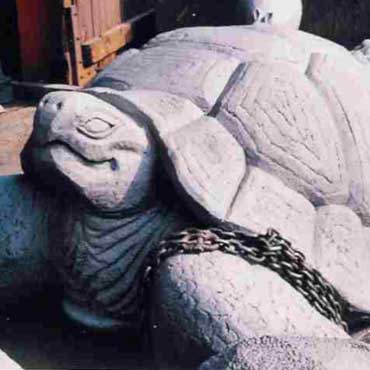

The dragon head is cast from polystyrene into iron, this becomes the figure head of a bridge built to look akin to a Viking long boat.

Beechwood Bridge is to be erected at Rawmarsh South Yorkshire and is commissioned by Rotherham Borough Council.

Jason Thomson

St Botolph's Hare

Commissioned for St Botolph's Primary School in Sleaford Lincolnshire the hare and boy are cast in aluminium and the wings are fabricated in Stainless Steel. The aluminium Hare is over 2m in length.

Amanda Wray

Cats at'om

A commission to work with a local youth group (13-16 year olds) to create an entrance feature to the new adventure playground at High Hazels Park in Darnall, Sheffield.

Sheffield City Council and the Friends of High Hazels worked in partnership to gain European funding and my involvement is part of the High Hazels Park Community regeneration Project.

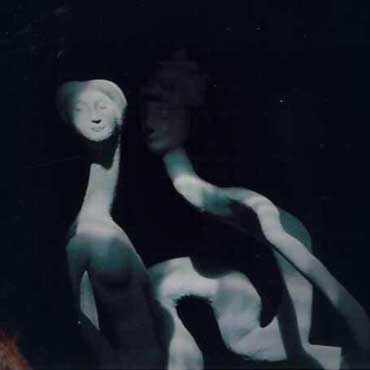

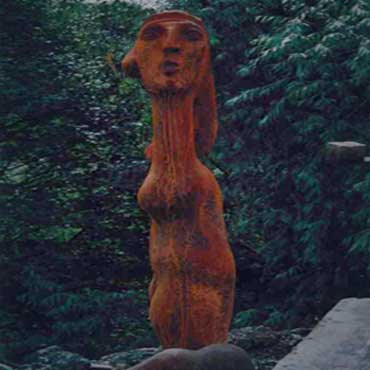

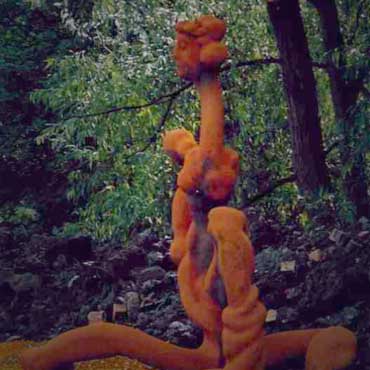

Unknown

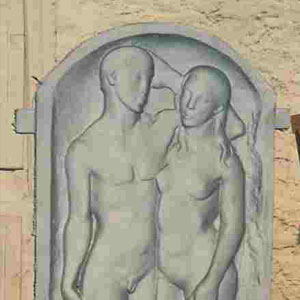

Adam & Eve

Casting from a plaster cast Cira 1940 artist unknown. Destined for a walled garden where it will be allowed to rust to complement the brickwork. The rear of the casting was made level during the moulding and lugs were added so the casting can be bolted to the wall. Background image is of the casting as it is removed from the sand still red hot. Height Approx 1500mm

Derek Howarth

The Ballerinas

Derek Howarth's polystyrene patterns catch the sun before they are taken to the Foundry. Derek has worked up-sizing Henry Moore's statues in the past. Recently he has been manufacturing sets for films such as Star Wars and Raiders of the lost Ark. Now he has produced his Twirly Whirly Girls. A selection of four Dancers during relaxation, adopting those poses that reflect the sinuous achievements of the professional da

The figures stand over 6 feet tall and proved an attraction to the fettlers responsible for cleaning off any excess cast iron metal after the statue has been cast.

There was however one exciting moment during the casting of these statues, a blowback occured during casting of the piece. Nobody was hurt and full protective gear is worn in anticipation that something like this may happen anytime during casting.

John Hopkins

Alert Deer

Fine art castings in aluminium and cast iron of Roe Buck and Doe commissioned by H. Downs

These sculptures are for sale, contact Nigel Downs

Contact us01484 428203Roe deer, native to all of the British Isles and Europe. Sculptured life size the deer stand approximately 65 cm ( 25") to the shoulder. Each deer is attached to a cast iron plate for stability bolted through from below into the feet. The plate is pebble/gravel in appearance on the top surface so as to be able to be hidden by a thin layer of gravel. Weights are approximately 250Kgs

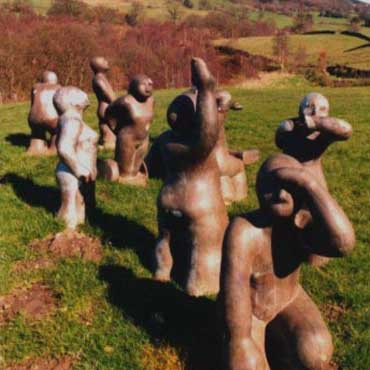

Marcella Livingston

Doughmen

A selection of 10 statues to be placed in strategic places around a 3 mile walk over reclaimed land.

Michael Dan Archer

Gateway withcrucibles

Granite and cast iron sculpture at Woodmere Chesterfield

Jason Thomson & CoralieTurpin

Pig at Slumber

Jason is a natural sculptor based inSheffield,his selection of farm animals, pig, sheep, goat and hen can be seen atThurnscoe between Barnsley and Doncaster.

The pig was carved out of polystyrene for us to use as a pattern, this process is risky as it can all go wrong and we lose the pattern and casting together. Owing to the temperatures of iron 1400+deg C the damage happens quickly fortunately no repeat sculpture had to be carved. Jason produced the pig shown, a goat, a sheep and hen on a post. The pig is approx 1m long by 450 x 300 tall.

Victoria Brailsford

Fox

Victoria is primarily a wood and stone carver, an artist in residence between Stocksbridge and Sheffield. Her main scope is contemporary pieces in stone with a yearning for a good glass factory to produce ideas. This Fox, standing approximately 1.5 metres high, has been placed in a park around Oldham for several years and was originally carved in wood. The statue was to be removed by the council as it started to rot through time. Local pressure however, called for a replacement and it was decided to offer a more long lasting material.

Cast Iron was chosen and because of our reputation we were asked if we could make an original off the rotten wood original. Victoria, repaired and patched the statue that had been removed from Oldham. We had previously met to discuss our requirements and how to achieve them to produce the most accurate reproduction from the wood

The three pictures so far show the pattern ( The original carving ) in the mould, we use cast iron boxes to hold the sand in place and carefully make joints and loose pieces which allows us to copy the detail off the pattern. The end casting is to be hollow, as solid it would way 4 or 5 tonne. Getting higher and higher the head will eventually be covered with sand, which will harden. The whole is then stripped away like a 3 dimensional jigsaw. The pattern is removed, a central part to hollow out the sand is made from the mould. The boxes and sand are all re-assembled and the mould is ready for casting.

After casting Victoria, cut in some of the missing fur lines and linished the surface to produce highlights and texture before allowing the natural rust to colour the fox.

This is a close up of the tail area showing the detail at patina as the piece begins to rust. We managed to retain many of the original carved hair lines, although Victoria had to re-cut the areas hat were too undercut for us to keep the detail when moulding.

The old and the new. Filler can be seen on the original wood version at the back when the repairs were done before the casting. Whie paint on the iron version shows off his markings, but will not last forever. A handsome creature, togged out and ready to be welcomed back to Oldham. At last as he stands in the yard ready to go.

Charlie Holmes

Richard Grainger Memorial, Newcastle-upon-Tyne

A tribute to Richard Grainger of Newcastle-upon-Tyne who as an architect contributed much to the city. The sculpture forms part of the walkway and will be polished by the feet of that city over time.

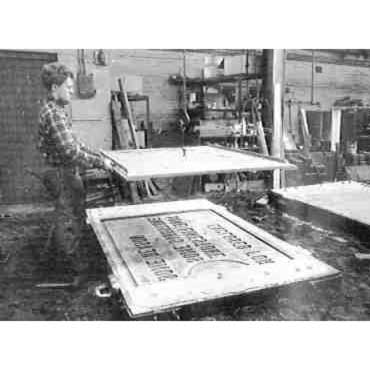

The sand we now use is recycled and turns black with the heat of the molten metal. To protect this sand surface from turning to glass we have to apply a carbon/ceramic paint.

The paint is spirit based and after it is applied it is dried by igniting and burning the spirit off. DO NOT TRY THIS AT HOME tends to make a mess of the curtains. Details of the casting's letters can be seen and the special anti slip surface designed for safety in the pedestrian area where the castings are to be displayed as part of the walkway.

After the mould is dried it is cleaned and blown out with an air line. It is then turned over and fitted on to the bottom half of the mould. The metal enters the mould through the line of holes on the left at a temperature of around 1500 deg. C

When the mould is closed and sealed, we have to place weights on top to stop the mould floating and lifting on the metal when it is poured in. 4 tonne of weights are used to stop the top from lifting

Finally the first casting is poured on the 2nd December 1999

Laying of the plates in Eldon Square Newcastle

Use of a site crane is imperative as the plates weigh up to 1400 kgs each. The plates are pre drilled and fitted with lifting eyes. When laid the lifting eyes are unscrewed and the tapped holes are filled with studs.

The castings go together well and the general opinion is good and favourable. Photographs by the artist Charlie Holmes.

The finished plate, unfortunately with water spilt on from the sheet covering it for the opening. The orange hue is the plate oxidising and as people start to walk over it the colour will change to grey. Charlie Holmes the artist on the right and Ian the architect on the left. The plate attracted a lot of attention from the passerbys. Later looking from 'Alister's' office window the interest was splendid to watch ,with some people just glancing and walking on, others walking straight over and not noticing it at all. Others walking past and returning. The centre section provided people doing a circular walk to read the writing around the edge. Two couples did stop to say they liked it and how as it was positioned on the ground it was not competing with other structural sculptures in the Grainger Town area.

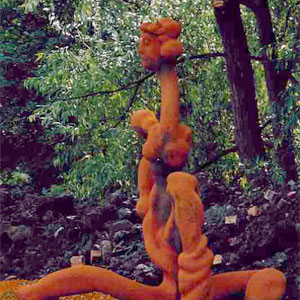

Phillip King

Peaks and Chimes

Again a challenging casting owing to itssizeand the fact it was from a polystyrene pattern that fell apart.

Janis Kounellis

HCWW

We produced a series of discs fitted to the existing columns of the Dean Clough Gallery. This exhibit is repeated.

Picture courtesy of Susan Crowe

Lawrence Weiner

Steel pennies don't come or go to Heaven

Used to replace previous iron weigh scale. On permanent display at Dean Clough.

Steel Pennies Don't Come From Or Go To Heaven

The unveiling was lacking in the normal refreshments of canapés and wine, the artist had acquired a taste for more northern fayre such as, pork pies, tripe, black and white puddings etc. All washed down with a choice of Beamish stout, Ben Shaws yellow lemonade or Ben Shaws Dandelion and Burdock.

Photographs courtesy of Susan Crowe

Edward Allington

River Exe Project

Several castings were made to adorn the side of the river bank.

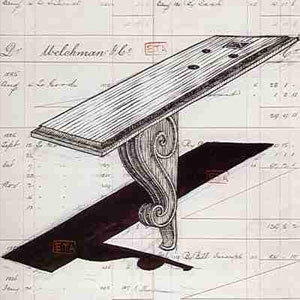

Edward Allington

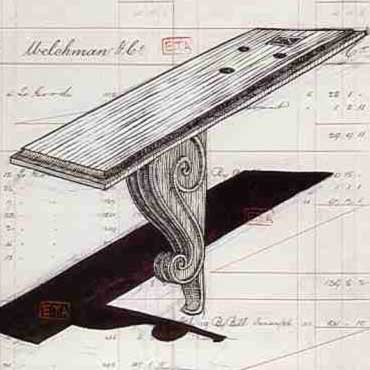

Column

First picture shows the design for The River Exe Project.

Several castings were made to adorn the side of the river bank.

The Pattern for a column under construction, the column is actually curved so optically it will appear straight.

The mould is cast in our sand floor, the metal is poured in and two days later when it has cooled the casting is lifted.

To ensure the two halves fit neatly together the joints are machined flat.

The two halve were drilled and stainless steel bolts with large decorative brass washers were used to fasten the two halves together.

Finally the casting sits on its resting place, outside a bank in Germany.

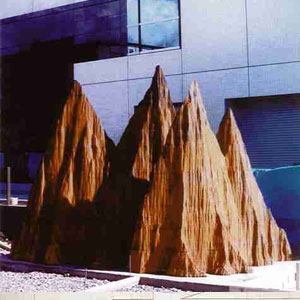

Anish Kapoor

Mountain

One of our favourite sculptors, this sculpture took a lot of time and effort to produce. This piece now resides in Japan.

This was our favourite, it took weeks to prepare the patterns, constant jig sawing to follow the contours. It was cast in segments 12" deep and then the joints were machined and each layer assembled until we reached the peak of our casting. We moved mountains and the final picture is at its location in Japan. The background on this page is part of the picture, each layer is 18mm thick. The total height was approx. 4.5 metre

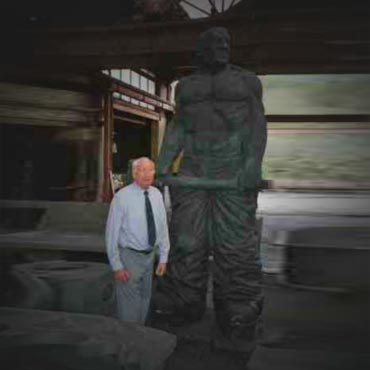

Antony Gormley

Figures

We have cast various figures in various shapes and sizes.